As the leader of the aluminum composite panel industry, Pivot takes responsibility of innovation, and with a profound knowledge of the market demand, our group keeps on research, and innovation, bringing out products that have won recognition widely from home and abroad for their outstanding features of high quality, diversification, high technological content, and environmental protection.

We provide our customers qualified aluminum composite panels and an overall professional systematic service of engineering and construction.

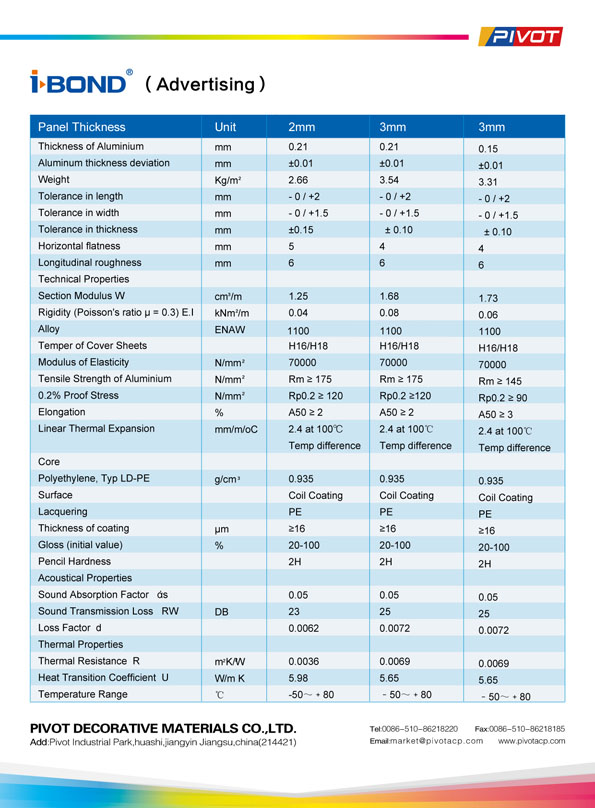

| Product Information | |

|

iBond aluminum composite panel is a kind of new-fashioned composite material through serial processing, with the paint coating aluminum sheet as the surface after surface preparation and the high pressure low density polyethylene compound as the core layer, the conformation of which has excellent acid, alkali and corrosion resistance to be the most preferred material for modern curtain wall decoration and interior design. |

| Raw Material | Product Specifications | ||||||||

|

|

|

Product Features 1. Weather resistance: the extra-strong weather and ultraviolet resistance and good acid and alkali resistance can stand test of severe environment. Long duration of color and gross, service life can be over 15 years, applicable temperature: -40℃-+80℃;Peeling strength exceeds that of the national standard. 2. Economical: a variety of quality coatings are applied on the product, which allow no forming of dirt on the surface and affect in self-cleaning with natural rain water, free from expenses on maintenance of high rise large buildings. 3. Ease of application: aluminum composite panel is easy for cutting, cropping, ploughing, bending to arc, right angle and other shapes, fully satisfying the needs in decoration and design of various moulds. 4. Fire-resistance: the outer aluminum-foil layer of the aluminum composite panel can obstruct heat transmission at the initial stage of combustion to protect the polyethylene core, the fire-resistance of which meets the national standard. 5. light weight: the aluminum composite panel is compounded of aluminum alloy and quality plastics, with the weight lighter than other decorative materials, which reduces the dead load of the material for the convenience of construction and thus has considerably shorten the construction period. 6. comparison on thickness and weight under the same rigidity ibond compared with aluminum single plate

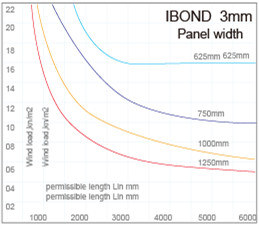

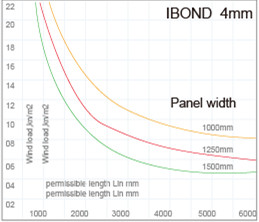

7. wind load and permissible dimensions of the panel.   The above diagram shows the wind load and the maximum length permitted under specific panel width. (no need to set the panel length of the reinforcing rib) NoticePermissible stress: 53 n/mm2 (including safe factor)value applicable for the panel simply supported on four sides Please inquire our professional staff for other techniques on installation system.

9. Environmental protection: good oxidation, no change on the surface layer, no pollution to the environment, resistance to contamination of the extraneous acid, solvent and detergent, making it not easy for them to stick to the surface.

10. color diversity: We offer more than 50 colors for the choice of our customers, and we also custom special colors at the request of our customers. 12. Flatness: the flatness of aluminum composite panel satisfies the demand for high visual effect on modern architectures. |

|

The brand management concept of “Pivot product, warranty for the quality” we offer is not only our goal, but also an obligation. We conform to the professional standard of “novelty, aesthetics, energy conservation, environmental protection and safety” by setting up a fashionable and natural image for the brand, in providing top-ranking after-sale services and in achieving the success and reputation of the brand with sincerity and wisdom.

1.Prevent the product from water during transportation, processing and installation for fear that it may damage the aluminum panel.

2. Keep the product laid flat no matter in transportation or in storage. If side laid, the panels should be kept vertical to the plane, compact to each other. The storage period should not be over 6 months.

3 . This product is suitable for processes of sawing, cutting, edge planning, riveting, grooving, bending and spray painting.

4. v-shaped cutting tools should be applied in grooving, the width of the tank bottom is2.5-4mm, the blade should be sharp, the rotating speed is 2000-3000 rotations/min, the cutting feed should be 3-5 m/min to prevent the peeling off of the aluminum panel caused by the melting of the adhesive by over heating; 0.3-0.5mm thick plastic core should be kept between the lowest point and the aluminum panel according to the aluminum thickness. The distance between the centerline and the edge of the aluminum plastic panel should be bigger than 20mm.

5. Use uniformed force and one shot modeling in flanging instead of abrupt force and repeated bending.

6. Don’t fill in silica gel when it’s raining

7. Use bending tools in the decoration of cambered surface. Bend the aluminum plastic panel slowly into required curved surface with curvature radius not less than 20cm.

8. Mount the panel according to the arrow direction in order to prevent visual chromatic aberration by the light reflection.

9. Don’t peel off the protective film before the completion of the construction to prevent scratching to the surface coating film; peel off the protective film within 45 days after the completion.

10. Don’t apply resin or hardened adhesives in the mounting of the internal wall plate, otherwise there’ll be unflatness. It is better to use plywood or other related materials as the bottom board of the internal aluminum plastic wall plate instead of sticking the aluminum plastic panel directly to the cement wall.

11. Framework of corresponding dimensions should be inner lined after flanging of the aluminum plastic panel with the dimension not over 600mm*600mm. the internal wall plate should be used indoors instead of outdoors.

12. Neutral detergent or medical alcohol can be applied softly and gently in cleaning of the contaminated panel surface. Chemical solvents or acid & alkali solutions like butanone, acetone, xylene and lacquer thinner are prohibited.

With iBond® you buy a lot more than aluminum composite panel Being the leading supplier of aluminum composite panel in China means that we are committed to our customers. And we promise to deliver the best material and supply first-class service to our customers.

1. Quality

iBond® has very strict standards on quality. We try every effort to stabilize our product quality, quality is always our first concern. The quality control is applied to the whole production process, including the quality inspection on raw material, quality inspection during and after production. A detailed record is filed for reference afterwards. All the work is to make sure we deliver top-quality iBond® product.

2. Service

Our professional sales team for iBond® will provide professional , fast and heartfelt service to our customers

3.Environmental Friendly

All the waste gas, waste water will be treated properly before discharge, which meets with the environment friendly requirement of ISO—14001.

4. R&D

iBond® has a professional research and development team, who will develop new products continuously with the cooperation of universities to meet any customer requirement

5. Brand Promotion

We already have prestigious customers who trust us, and our brand is becoming more famous every passing day thanks to our promotion and the quality of our products.

6. Social Responsibility

As a brand with high sense of social responsibility, iBond® is always ready to repay the community. we set up a scholarship in universities in Jiangsu and Fujian Province, we also organized donation for the earthquake people in 2008 and the drought victims of Yunnan Province in 2010.

1.What is iBond aluminum composite panel?

iBond aluminum composite panelis short form for Aluminum composite panels, also known as aluminum composite materials or acm. It is a kind of new material, composed of laminate 2 color painted aluminum sheets with plastic cores, in the plate form and with the thickness from 2mm-7mm.

2. Why use iBond aluminum composite panel?

iBond aluminum composite panel is a new material for advertising and architecture, it has many features than traditional materials, it is solid, string hard but light weight, it has multiple colors and good weather resistance, also it is easy to be fabricated into different shapes.

3.How to classify the iBond aluminum composite panel and What is the application of iBond aluminum composite panels?

For advertising, iBond aluminum composite panel could be used for substrate, printing board, indoor signs, billboard etc.

For outdoor signage, iBond aluminum composite panel could be used for big s/gnage, towers, different shapes if needed, dealer’s cladding etc.

For decorative, iBond aluminum composite panel could be used as wall panels, frames in door and windows system, roofs and ceiling etc.

For architecture, iBond aluminum composite panel could be used as curtain wall panels.

There’re also some new applications for iBond aluminum composite panels just like exhibitions materials, decoration in trucks, trains, boat or metros, etc.

4.What is the normal thickness of your iBond aluminum composite panel?

Normally thickness will be 3mm or 4mm, Thickness range is 2mm to 7mm

5.What is the normal thickness of the aluminum skin?

Normally thickness will be 0.21mm, 0.3mm, 0.4mm or 0.5mm

6.What is the normal size of your iBond aluminum composite panel

Normal width would be 1000mm, 1220mm, 1250mm, 1500mm, 1525mm and 2000mm

Not limited on length, depend on the package and transportation ways.

7.What is the weight of iBond aluminum composite panel?

Normal iBond aluminum composite panel:

4mm with 0.5mm skin: 5.5kgs/sqm, 4mm with 0.4mm skin: 5.15kgs/sqm, 4mm with 0.3mm skin: 4.78kgs/sqm,

3mm with 0.3mm skin: 3.86kgs/sqm, 3mm with 0.25mm skin: 3.68kgs/sqm, 3mm with 0.21mm skin: 3.54kgs/sqm

6mm with 0.3mm skin: 6.65kgs/sqm, 6mm with 0.21mm skin: 6.33kgs/sqm.

2mm with 0.3mm skin: 3kgs/sqm, 2mm with 0.21mm skin: 2.6kgs/sqm

Fire-resistant iBond aluminum composite panel:

4mm with 0.5mm skin: 6.61kgs/sqm, 4mm with 0.4mm skin: 6.33kgs/sqm, 4mm with 0.3mm skin: 6.05kgs/sqm,

.jpg)

2. What is the core materials inside of iBond aluminum composite panel?

Vergin or recycled LDPE(low density polyethylene)

3. Do you have 3 series or 5 series Alloy for the aluminum skin?

Yes we have 3003 or 5005 alloy aluminum for skin

4. What is the bowl tolerance of your iBond aluminum composite panel?

It is 5mm

5. What is the surface tension of your iBond aluminum composite panel?

For normal PE coating iBond aluminum composite panel, surface tension would be around 38 dyne, for digital iBond aluminum composite panel, surface tension would be above 38 and reach 40 dyne.

6. Could we use iBond aluminum composite panel for digital printing directly?

Yes, Digital iBond aluminum composite panel could be printed directly without any treatment on surface.

7. Could you provide the installation draws of your iBond aluminum composite panel?

Yes we have more than 2 types of installation draws. You could go to the download page and download our draws.

8. Which paint type do you recommended for exterior cladding use?

We recommend the PVDF, PVDF Nano, Chameron and FEVE coatings, either of these paints have very good performance on weather resistant.

9. Do you have a fire-resistant iBond aluminum composite panel?

Yes we have fire-resistant iBond aluminum composite panels with fire-proof core materials inside, good performance for fire-resistant.

10. What your iBond aluminum composite panel’s fire-resistant level?

B1, B2 and the A2 level

11. Do you have a NANO-faced iBond aluminum composite panel? What is the warranty of this iBond aluminum composite panel? iBond aluminum composite panel

Yes we have iBond® NANO, with NANO technology, the surface is self-cleaning character.

The warranty for the Nano-feature is one year。

12. How long could the antibacterial effect sustained of your antibacterial iBond aluminum composite panels?

It could be at least 2 years.

13. What is the warranties of your iBond aluminum composite panels?

PE coating interior use: 8-10 years, some colors like white, silver can reach 10 years.

PE coating exterior use: 5 years

PVDF coating exterior use: 15 – 20 year.

FEVE coating exterior use: 10 years

14. Do you have a formal warranty letter?

Yes, please see the warranty letter form below.

15. Do you warrant other things than the paint quality?

Yes, you can see the terms on our warranty letter

16. How did you handle the issues in case of products false against the warranty letter?

Normally we will do some researches on the claim, need some pictures or samples etc… (Probably,) if the problem was caused by our products, we will cover the losses.

1. Are you an ISO certified company?

Yes we are an TUV ISO 9001 quality certified and an ISO 14001 environment certified company.

2. What are the main certificates your company have?

TUV, UL

3. Which fire-resistance tests you have past?

EN13501, ASTM E84 ASTM E119, DIN4102 BS476, PSB, Russian Fire test,

4. Do you have a UL certificate?

Yes we have a file No. E341462 under UL

5. Do you have RosH or Reach tested on your products?

Yes we have a lot of TUV tests and reports on the Reach and RoSH test.

6. Do your PVDF paint has a Kynar500 or Hylar5000 certificate?

Yes our paint suppliers have such certificate, see below.